There are different types of solar panels. In case you didn’t already know, not all solar panels are the same. Today, there are 3 types of solar panels:

• Photovoltaic solar panels

• Solar thermal panels

• Hybrid solar panels (photovoltaic + thermal)

Below, we will explain what each of them consists of and what you can do with each of them:

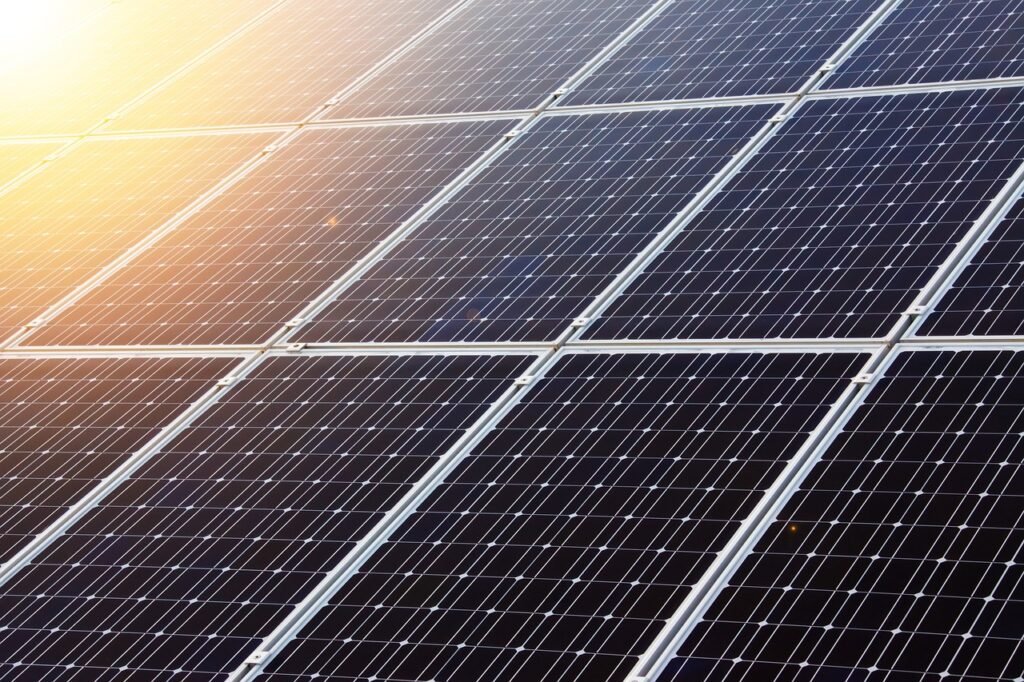

Photovoltaic solar panels

The first type of panel we are going to talk about is the photovoltaic solar panel, which transforms energy from the sun into electricity.

With increasingly lower prices, photovoltaic modules are a great, clean alternative to generate electricity (or part of it) in our homes, hospitals, businesses, schools, etc.

Generally, this type of panel is made up of photovoltaic cells that transform light energy into electrical energy through a process called the photoelectric effect.

In a simple and summarised way, this process occurs when photons (one of “the particles that make up” light) impact the solar panel against the silicon. Upon impact, the photons bombard the silicon atoms, breaking the electrons and releasing some of them, which will generate the electric current.

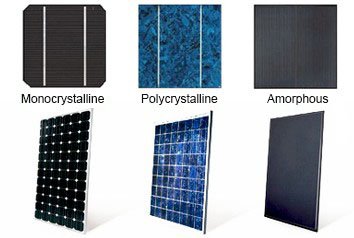

Also, there are several types of photovoltaic solar panels, depending on the material that composes the photovoltaic cells. Currently, the most common photovoltaic solar panels are:

• Crystalline: In this case, they can be Monocrystalline or Polycrystalline.

• Amorphous

• Others not composed of silicon, such as Thin Film or Organic Films.

Monocrystalline Photovoltaic Panels:

As its name says, a monocrystalline photovoltaic panel is made up of monocrystalline cells. They are that type of cell that, with the naked eye, we can differentiate by their “black” colour and with the corners cut with a chamfer (the result of cutting the cell).

Monocrystalline panels have a higher efficiency than polycrystalline panels (in Standard Test Conditions). Its laboratory yield is close to 24%, and its commercial yield ranges between 17 and 20%. This is an important factor when we don’t have much surface area to install panels since, this way, we can achieve greater power with the same space. Their useful life is also usually longer than that of Polycrystalline panels, and they generally perform better with diffuse radiation. These factors make their price slightly higher than polycrystalline ones.

In the short term, they are somewhat more expensive than polycrystalline ones, although in the medium-long term, they are more profitable due to their higher performance.

The most common way of manufacturing single-crystalline silicon (sc-Si) cells consists of starting an ingot of a single crystal of silicon, obtained by the Czochralski (Cz) or floating zone (FZ) methods, and cutting it into wafers that constitute the substrate on which the entire remaining process will take place (p-n union, metallisation, etc.).

In addition to this, monocrystalline solar panels are the most efficient of all those available in the sector.

Polycrystalline Solar Panels

As we mentioned with monocrystalline models, polycrystalline solar panels are composed, in this case, of polycrystalline cells. We can differentiate them by their “bluish” colour. Besides, they do not have the chamfer in the corners like the monocrystalline ones.

Polycrystalline panels have a laboratory yield close to 19%, and their commercial yield ranges between 13 and 15%. They are cheaper than monocrystalline panels and have better performance at high temperatures. That is, under these conditions, they can generate more energy than the rest of the panels.

Polycrystalline silicon cells (mc-Si) also use silicon wafers as a substrate. But unlike monocrystalline cells, these come from cutting a block of silicon that has been allowed to solidify slowly in a crucible. And it’s made up of many tiny silicon crystals.

This type of processing is less expensive than the previous one but considerably reduces the efficiency of the cells. Polycrystalline solar panels can be interesting if you are looking for something cheap. But in the long term, monocrystalline ones are more profitable.

Amorphous Solar Panels

Also known as amorphous silicon solar panels, they are made of silicon in a non-crystalline structure. This means that silicon doesn’t have an ordered structure, making it easier to manufacture and lowering costs. However, this also affects the efficiency of the panel compared to crystalline panels.

They have a relatively low efficiency compared to other types of solar panels, such as crystalline ones. Their advantage lies in their lower production cost and their ability to operate in low light conditions.

•Amorphous solar panels are more flexible and lighter compared to crystalline panels. So, they are suitable for applications where flexibility is crucial, such as building-integrated applications or wearable devices.

Also, amorphous panels can be less expensive to manufacture compared to some other types of solar panels because of the simplicity of the production process.

Thin Film Panels

Thin film panels generally have a laboratory yield close to 13%. And their commercial yield ranges between 7 and 9%. These panels were created to reduce production costs and address the possible shortage of silicon, leading to research on cells made of other materials. So, one of their main advantages is that, despite requiring more space to generate the same energy as polycrystalline or monocrystalline panels, their price is much lower. Also, they have good performance at high temperatures, and their aesthetic appearance is very attractive, making them commonly used in architectural applications.

The most common thin film panels are those made of copper, indium, and selenium (CIS) or copper, indium, gallium, and selenium (CIGS). And finally, there are thin-film panels based on cadmium and tellurium (CdTe).

There is a significant increase in demand for transparent and semi-transparent thin film panels because of their attractive architectural integration in facades. These panels are also available in different colours, greatly expanding their integration possibilities in various locations.

The operation of a thin-film amorphous silicon solar cell is the same as crystalline ones, but its production is very different. The characteristic aspects of this technology are:

• Simple and easily automated manufacturing process.

• Need for little active material and reduction in energy expenditure and cost.

• Ease of creating flexible modules with optimal quantum efficiency in a wide range of the spectrum.

As can be seen in the image, amorphous silicon solar panels do not consist of the union of individual cells as in crystalline solar panels, but rather a sheet cut to size in which we can observe thin strips that separate the cells, created and connected during the development of the module itself, whose framing facilitates its handling and assembly.

The voltage range is also wider than that of crystalline silicon, ranging from a few volts to tens of volts. So, they are ideal for solar pumping systems.

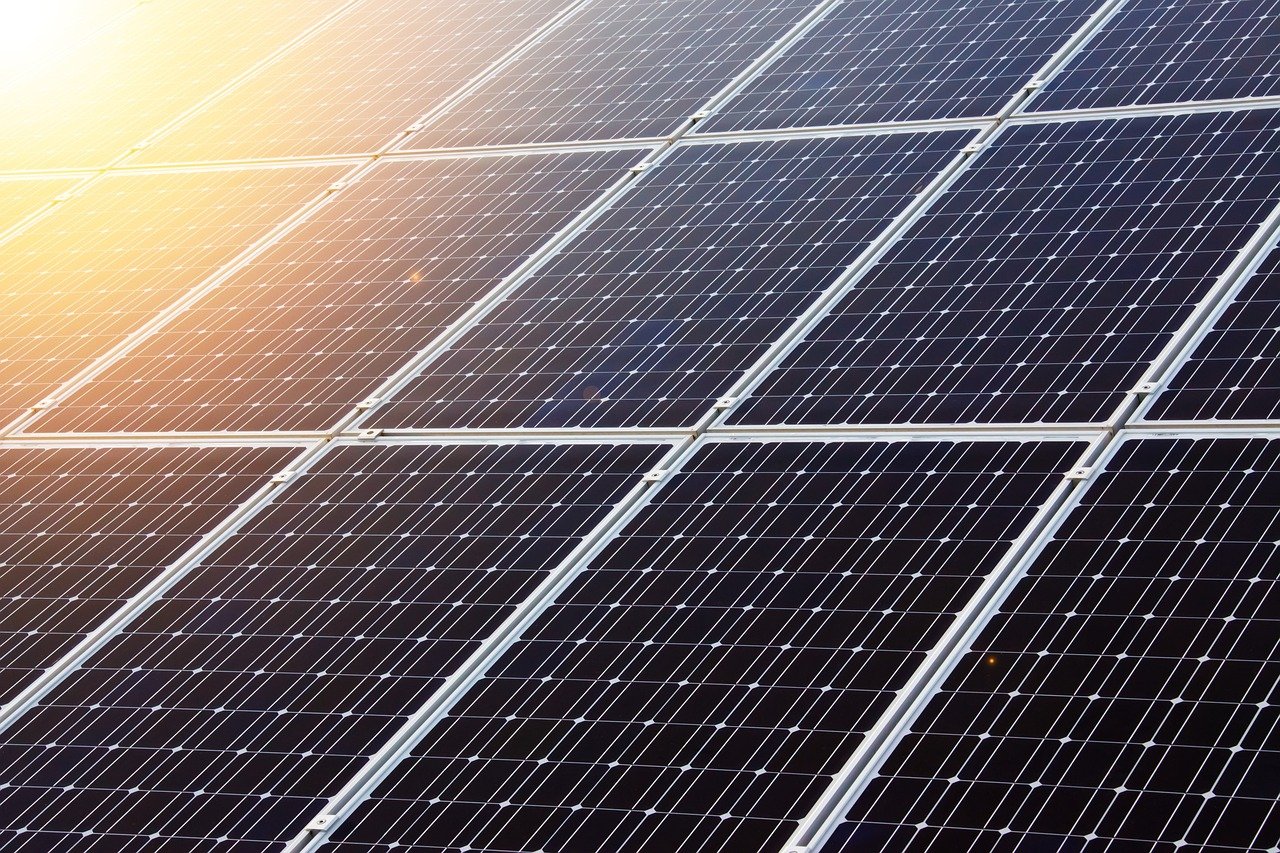

Choose between Monocrystalline or Polycrystalline Solar Panels

Polycrystalline solar panels are made up of cells whose silicon does not come from a single silicon crystal but from many small melts in groups. For this reason, since it is not a single crystal, it is not as pure as a monocrystalline cell, and its efficiencies and performances are always somewhat lower than a monocrystalline panel. There are also the so-called “Mono Black”, which are black solar panels. They are perfect for home because of their excellent integration and minimal visual impact.

Monocrystalline solar panels consist of cells sourced from a single crystal, ensuring optimal purity and improved efficiency. Without a doubt, when considering efficiency, monocrystalline panels surpass polycrystalline ones. The highest-performing solar panels in the current market predominantly feature monocrystalline technology, achieving efficiency ranging from 180 Watts to 220W per square meter. In contrast, polycrystalline solar panels typically exhibit a performance of about 170 Watts per square meter.

Comparison table of solar panel types

| Type | Material | Structure | Efficiency | Cost | Appearance | Flexibility |

| Monocrystalline | Made from a single crystal structure of silicon | Uniform and continuous crystal lattice, which results in higher efficiency | High efficiency, typically ranging from 15% to 22%. More efficient in converting sunlight into electricity | Generally, these panels have a moderate to high production cost | Typically have a uniform dark color and a more conventional appearance | Rigid and less flexible. Suitable for standard solar installations |

| Polycrystalline | Composed of multiple crystal structures | Less uniform than monocrystalline, with visible grain boundaries. Slightly lower efficiency compared to monocrystalline | Moderate efficiency, generally in the range of 13% to 18%. Slightly less efficient than monocrystalline. | Generally, these panels have a moderate to high production cost, but they are cheaper than monocrystalline | Typically have a uniform dark color and a more conventional appearance | Rigid and less flexible. Suitable for standard solar installations |

| Amorphous | Utilizes non-crystalline silicon | Lacks a distinct crystal structure, making them more flexible. Generally has lower efficiency compared to crystalline panels | Lower efficiency, typically in the range of 6% to 12%. Flexible but less efficient than crystalline panels. | Lower production costs compared to crystalline panels, making them more economical. | Can be made semi-transparent and are available in various colours. More aesthetically flexible | Flexible and can be used on curved or irregular surfaces. Suited for applications with flexibility requirements |

| Thin-film | Can use various materials, such as cadmium telluride (CdTe), copper indium gallium selenide (CIGS), or amorphous silicon | Deposited in thin layers on a substrate. Offers flexibility and can adapt to different surfaces | Efficiency varies depending on the material used. Generally, it can range from 10% to 12% for CdTe and CIGS, and lower for amorphous silicon | Production costs vary. CdTe panels can be cost-effective, while CIGS panels may be more expensive. Amorphous silicon panels are relatively economical. | Flexible and can be integrated into various surfaces. Appearance varies based on the specific material used | Highly flexible and adaptable to different surfaces, including curved or non-planar structures |

Advantages, disadvantages and uses of each type of solar panel

Monocrystalline Solar Panels

What we like

What we don’t like

Uses

- Residential and commercial rooftop installations.

- Small-scale applications with limited space.

Polycrystalline Solar Panels

What we like

What we don’t like

Uses

- Residential and commercial solar installations where cost is a critical factor.

- Utility-scale solar farms with ample space.

Amorphous Silicon Solar Panels

What we like

What we don’t like

Uses

- Portable solar chargers and gadgets.

- Building integrated solar installations where flexibility is crucial.

Thin-Film Solar Panels

What we like

What we don’t like

Uses

- Building-integrated solar panels.

- Portable and flexible solar applications.

- Large-scale solar farms with expansive installation areas.

Types according to the number of solar cells:

We can categorize solar panels according to the number of solar cells they incorporate:

- 36 Solar Cells: With an approximate power of 150W, suitable for 12V batteries.

- 60 Cells and 120 Half Cells: Offering a power range between 320W and 340W for self-consumption, often referred to as 24V solar panels.

- 72 Cells and 144 Half Cells: Providing a power range between 385W and 415W, suitable for self-consumption and charging 24V batteries.

- Single Cells: Advanced technology where manufacturers join photovoltaic cells, behaving like a “supercell.”

However, the use of half cells, while improving performance in shadows, presents a disadvantage with duplicated soldering and metal contacts, making them more susceptible to failures.

Flexible Solar Panels

These types of panels are flexible and weigh half of conventional panels. This is because they don’t use a frame or glass but are encapsulated in polymers to facilitate flexibility.

A flexible solar panel has flexible solar cells, and 99% of those that exist are not. For this reason, for this type of panel, you must always choose those with Maxeon-type solar cells. This is the way to ensure that the solar panel is flexible and that there are no micro-breaks in the cells when bending the panel.

Solar Thermal:

Another type of solar panel is the solar thermal or solar collector. This panel transforms solar energy into thermal energy or heat, serving various purposes, including heating swimming pools, preparing water for sanitary use, and generating steam. Thermal panels are classified into:

- Low-Temperature Collector: Reaches a maximum of 50ºC, primarily used for heating and domestic hot water in domestic systems.

- Medium Temperature Collector: Similar to low-temperature collectors but with a transparent cover preventing heat loss, enabling temperatures up to 90ºC.

- High-Temperature Collector: Features an additional cover that creates a vacuum and reaches temperatures up to 150ºC. So, you can often use them to produce steam for electricity generation

Hybrid Solar Panel

The hybrid solar panel is a combination of photovoltaic and thermal panels. So, they simultaneously produce electricity and hot water. This hybrid technology offers more energy production per surface area compared to individual photovoltaic and thermal panels. Its main advantage lies in reducing the necessary space for solar energy utilization. Then, they are ideal for places with limited roof space, such as hotels, heated pools, or homes requiring domestic hot water.

What Type of Solar Panel Should I Use?

While it’s common to classify solar panels based on technology, it’s also practical to categorize them according to their applications. Let’s distinguish them based on their uses:

Solar Panels for Self-Consumption and Houses

- Widely used today, especially with the increasing popularity of these systems.

- Typically standard photovoltaic panels, either monocrystalline or polycrystalline.

- Power ratings usually range from 300W to 550W.

For residential and self-consumption purposes, the panels used are typically of monocrystalline technology (higher efficiency) or polycrystalline (lower efficiency), with power ratings ranging from 300W to 550W in the case of monocrystalline. For residential installations, we recommend using panels that are not excessively large.

So, we prefer panels with dimensions not exceeding 1.7 x 1 meter or 2 x 1 meter. A recommended efficiency of over 20% facilitates installation, and the modular design optimizes available surface area.

On the other hand, installation work in industrial warehouses is more straightforward. In such cases, we prefer solar panels with dimensions of 2 x 1 meters or 2.1 x 1.2 meters (typically 72 cells).

Solar Panels for Motorhomes and Isolated Systems:

Solar panels for vans are typically designed for 12V applications. The goal is to find a solar panel with a terminal voltage of approximately 18V to charge the motorhome battery. Placing a solar panel on a van or camper, for instance, enables battery charging when the vehicle is stationary, providing additional energy during sunless hours and when the caravan is not in motion.

Conclusion

In summary, the choice of solar panel type depends on factors such as efficiency requirements, cost considerations, available space, and the specific application or installation environment. Each type has its own set of advantages and disadvantages, making them suitable for different use cases.

Leave a Reply