Since the surfaces on roofs are not unlimited, self-consumption projects must optimize their space by having the most efficient solar panels. This is one of the reasons why the major manufacturers of photovoltaic modules work hard to find technologies that improve efficiency and increase the power of their equipment. Although PERC technology is not new, it has gained a lot of prominence in recent years. So, it is one of the largest market shareholders. In this article, we delve into it to understand its advantages and characteristics.

What are PERC solar cells and how do they work?

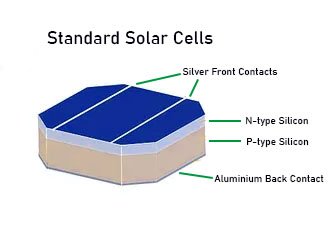

A PERC (Passivated Emitter Rear Cell) solar cell is a solar cell with an additional layer. This layer reflects part of the light that passed through the cell but was not initially absorbed. Then, this results in an increase in efficiency.

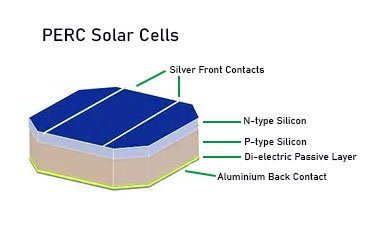

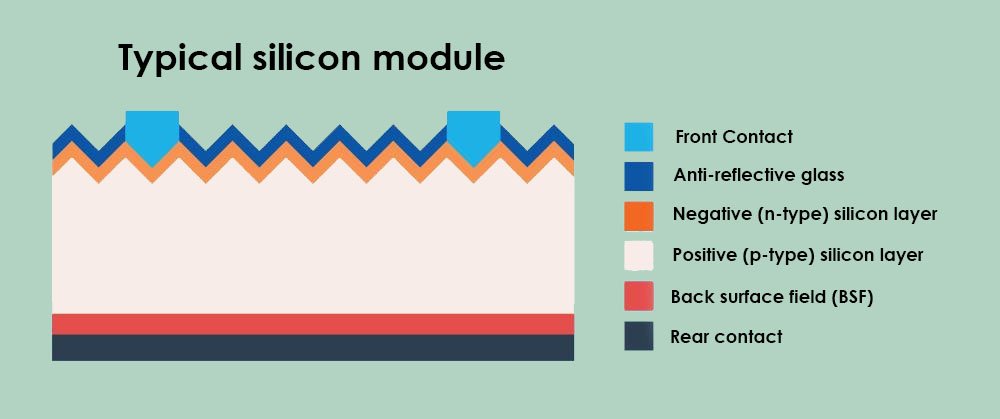

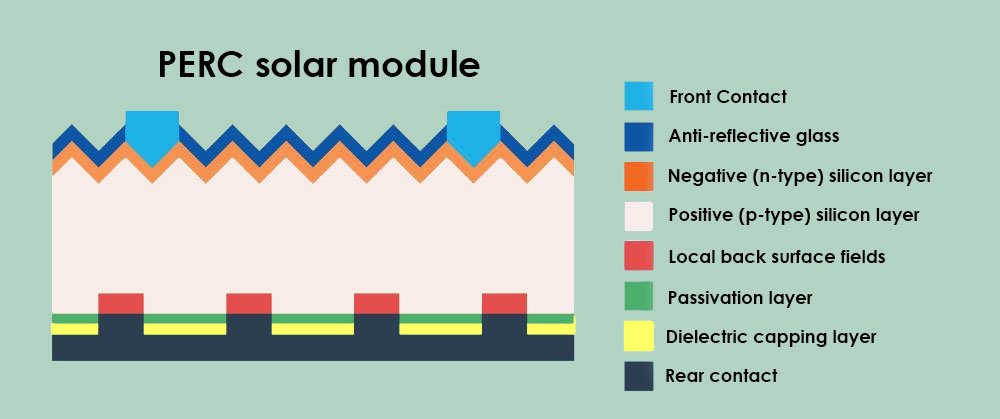

While traditional cells consist of three layers, the emitter, the base, and the bottom or rear layer, PERC cells add a fourth (reflective or passive layer) located between the base layer and the rear layer. This last layer allows part of the photons that have passed through it at the beginning to be reflected to the emitter layer.

This allows the cell to utilize “excess” light. And this light is reflected back into the cell by the dielectric/reflective plate, a feature not found in traditional solar cells.

How PERC technology works

So, the intermediate layer formed with a dielectric material (which does not conduct electricity) prevents the untrapped infrared light from reaching the rear layer. Instead of being absorbed by the final layer of the panel, PERC cells enable current to flow between the base layer and the emitter layer.

The basis of this characteristic of PERC cells is the use of certain wavelengths present in light. While a part reaches the emitting layer and the electric flow is produced there, the infrared light does not reach the final layer thanks to the dielectric material. This results in an important benefit that we will see below.

Advantages of PERC solar cells

Having this layer that takes advantage of an extra number of photons not captured by the traditional panel supposes a series of benefits that have positioned PERC technology as one of the most attractive.

Firstly, the efficiency improves over traditional solar cells, because of the reasons explained above. So, at the same level of solar radiation impacting a panel, the PERC will take advantage of a greater quantity of photons. Then, its performance will always be greater than a traditional cell per square metre.

Secondly, as we have seen previously, they have a lower temperature coefficient since the infrared light does not reach the back layer. So, it does not heat this part of the solar cell. If the temperature does not increase, the performance is maintained. And as is known, heat is not a good ally of technology.

The third major advantage is that PERC modules perform well even in low-light conditions. In other words, they generate more power than traditional panels in low-light conditions. Early in the day or when the sky is cloudy, conventional modules have lower performance than PERC modules because they cannot take advantage of certain wavelengths, as we have seen before.

Generally, PERC solar cells have an efficiency of over 20% and a lifespan of around 25 years.

PERC solar cell manufacturing process

One advantage of manufacturing this type of solar cell is the minimal additional cost. The production process is similar to traditional solar cells, with just two extra steps.

- The first step is adding a passive or reflective layer. This layer reflects light, so it doesn’t reach the back layer.

- The second is laser engraving. This process creates small holes in the passive layer, where insulating dielectric material is added.

Savings and investment in PERC technology

While the initial investment in PERC panels is slightly higher because of their advanced technology, they produce more energy per square meter. As a result, they often offer a faster return on investment than standard panels. Of course, always consider the specific characteristics of the project.

So, by requiring fewer panels, the initial installation cost may be lower. This brings another advantage: the flexibility to install them on small roofs or with different inclinations.

Main manufacturers of solar panels with PERC technology

Here are some of the top companies known for producing PERC solar panels:

Trina Solar

Trina Solar is an industry giant that produces high-efficiency panels using PERC technology. They focus on providing reliable and cost-effective solar solutions. So, their panels are widely used in residential, commercial, and utility-scale projects wordlwide.

https://www.trinasolar.com/eu-en/product

Canadian Solar

Canadian Solar is a global leader in solar manufacturing. They offer a range of high-efficiency PERC panels. Also, they are recognized for producing cost-effective, reliable solar solutions suitable for diverse environments.

https://www.csisolar.com/module

Marlec Renewable Power

Marlec is a pioneering UK-based manufacturer specializing in renewable energy products, including innovative solar panels and wind turbines. With decades of experience, Marlec is known for engineering reliable off-grid solar solutions that are designed to perform efficiently even in remote and challenging environments

Challenges of PERC technology

However, mass production of PERC technology still faces several challenges.

One of them is its light-induced degradation (LID). This is the effect of exposing the panel to natural light for the first time, which leads to a reduction in the module’s power percentage. In detail, this happens when the boron in the positive layer of silicon mixes with oxygen. This reduces the power production capacity between layers. And PERC cells, with their higher boron content, are particularly susceptible to this reduction.

The other challenge is to reduce the impact of Potential Induced Degradation (PID). This is a decrease in electrical production and the degradation of the module’s cells due to stray currents that circulate through elements of the panel that are not prepared for it.

What is the difference between monocrystalline solar cells and PERC solar cells?

Both use high-purity silicon to convert sunlight into electricity. The key difference lies in the technology used. Monocrystalline solar cells are made from a single-crystal structure. On the other hand, PERC solar cells are an improvement on monocrystalline or polycrystalline cells, which feature an additional passivation layer on the back. This layer increases the efficiency of the solar panel by reflecting unused light back into the cell. This gives PERC technology an advantage, especially in low-light conditions or space-limited installations.

Are PERC solar panels better?

PERC solar panels are generally considered better than standard panels because of their higher efficiency and improved performance in varying light conditions. They are particularly beneficial in situations where space is limited, as their higher power output allows you to generate more electricity from a smaller array. Additionally, they perform well in low-light and high-temperature environments.

Are PERC cells P-type or N-type?

PERC cells can be manufactured using either P-type or N-type silicon wafers. Traditionally, most PERC solar cells are manufactured using P-type silicon, which has been the industry standard for many years because of its cost-effectiveness and reliable performance. However, there is growing interest in using N-type silicon for PERC cells, as N-type wafers offer better resistance to degradation and can achieve even higher efficiency levels. The choice between P-type and N-type depends on the specific design and performance goals of the solar manufacturer.

Conclusion

In short, PERC technology increases the efficiency of solar panels and is already at an important stage of maturity. Although its contribution to new high-end panels is not as significant as in more conventional panels, we are dealing with a technology that is crucial in the industry because of its increased efficiency at a similar production cost.

Leave a Reply